About Noda

NODA THAILAND is a professional manufacturer specializing in the design and production of high-quality Thomson dies, Chrome dies (also known as Pinnacle dies), and die cut solutions for various industries. Our precision-engineered dies are widely used in the automotive, electronics, printing, packaging, and vacuum forming industries.

We provide customized die solutions suitable for a wide range of materials such as rubber, foam, plastic, film, leather, and corrugated cartons. With cutting-edge technology and Japanese-standard quality, NODA THAILAND ensures superior performance, durability, and precision for all your die cutting needs.

Trust NODA THAILAND – your expert partner in Thomson die, Chrome die, and Pinnacle die manufacturing.

NODA'S STRENGTH

We prioritize customer convenience above all. At NODA THAILAND, we believe that when our products make your work easier, that’s our greatest satisfaction.

We embrace every challenge without limits. No matter how complex the task, we are committed to delivering results. At NODA THAILAND, we continuously innovate our die cutting products—like Thomson die, Chrome die, and Pinnacle die—to keep up with ever-changing industry demands.

Playlist

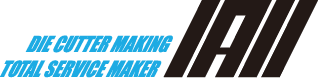

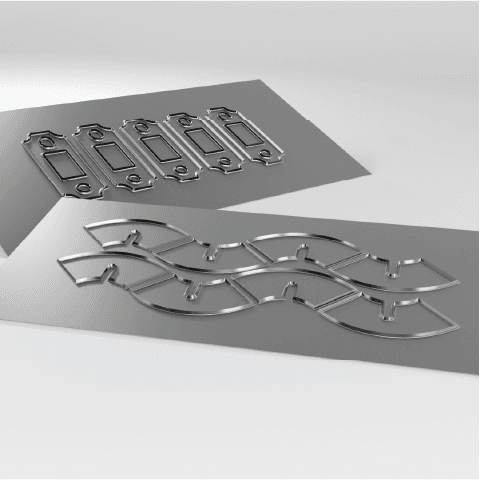

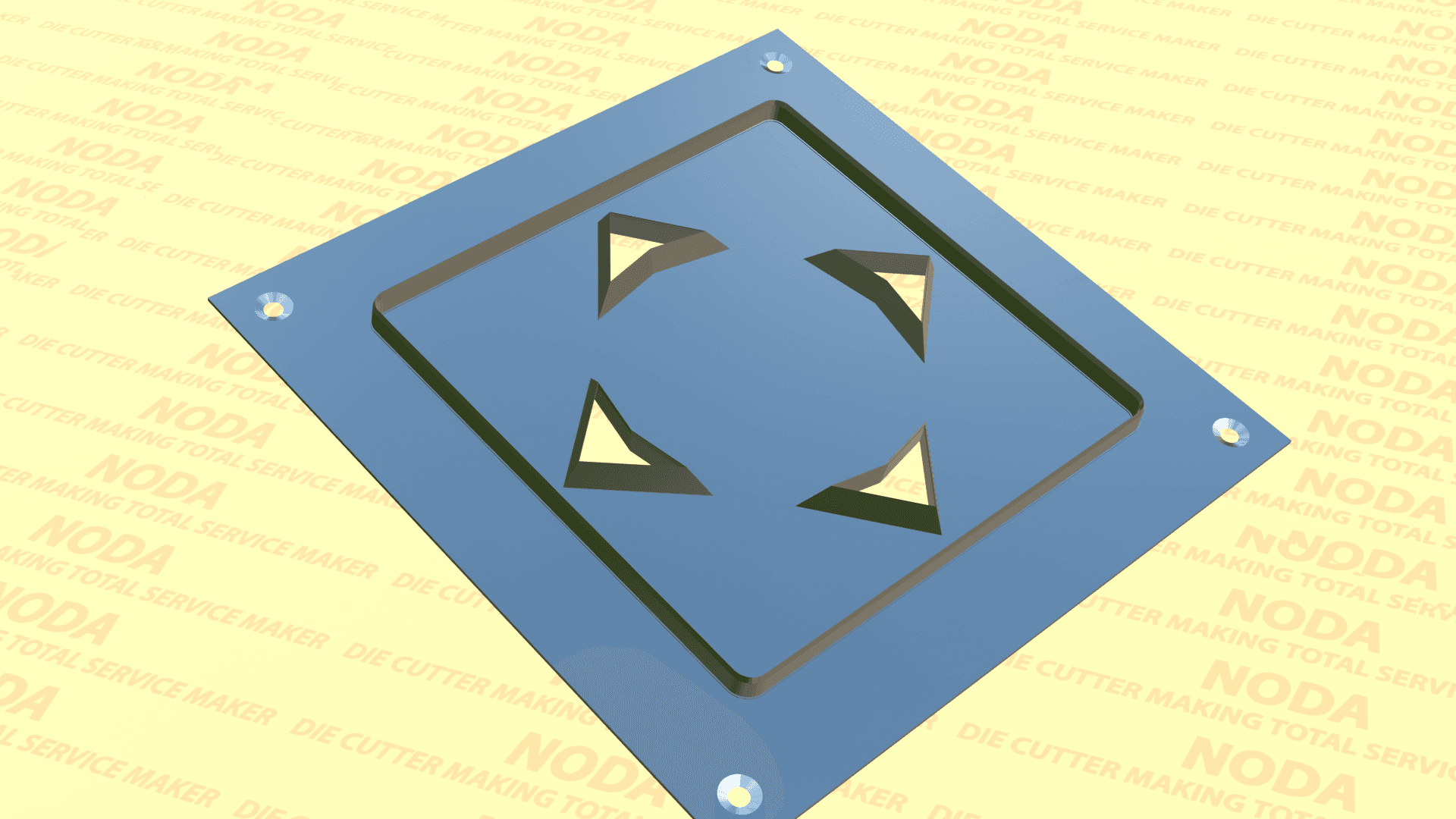

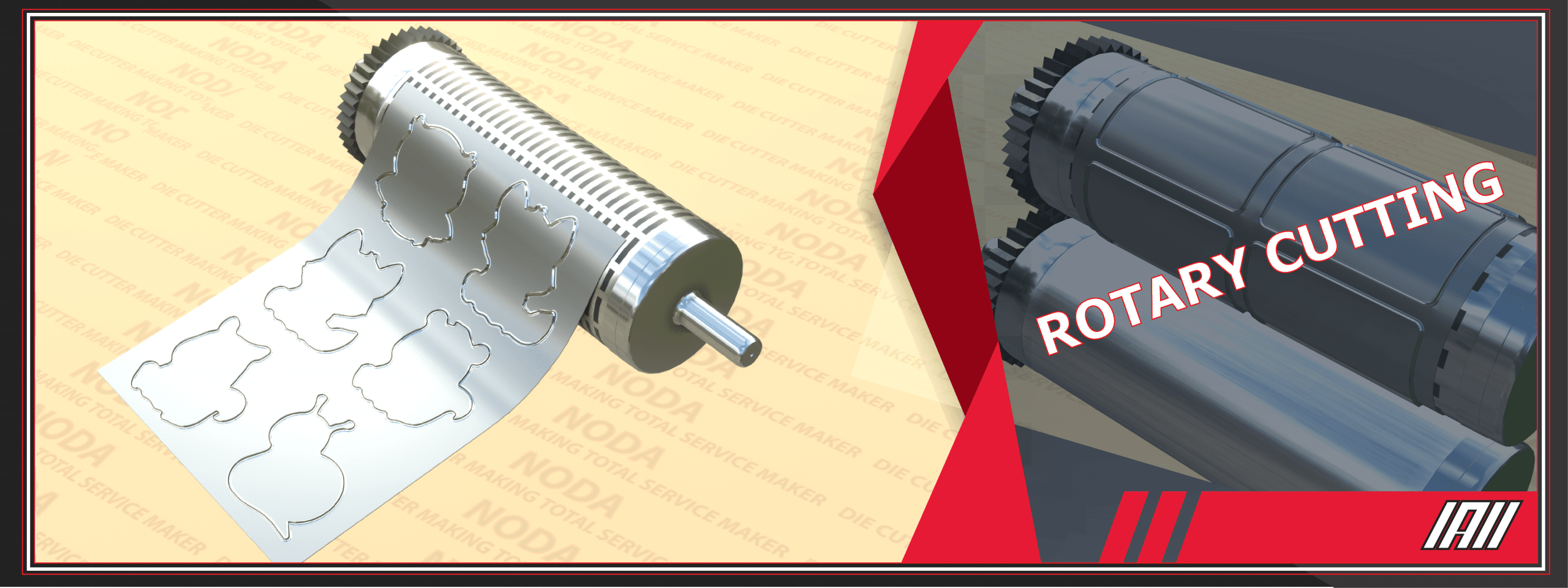

Pinnacle Rotary Cutting Dies are the perfect solution for high-precision label cutting. Designed for accuracy and efficiency, these chrome dies significantly enhance productivity in modern manufacturing.

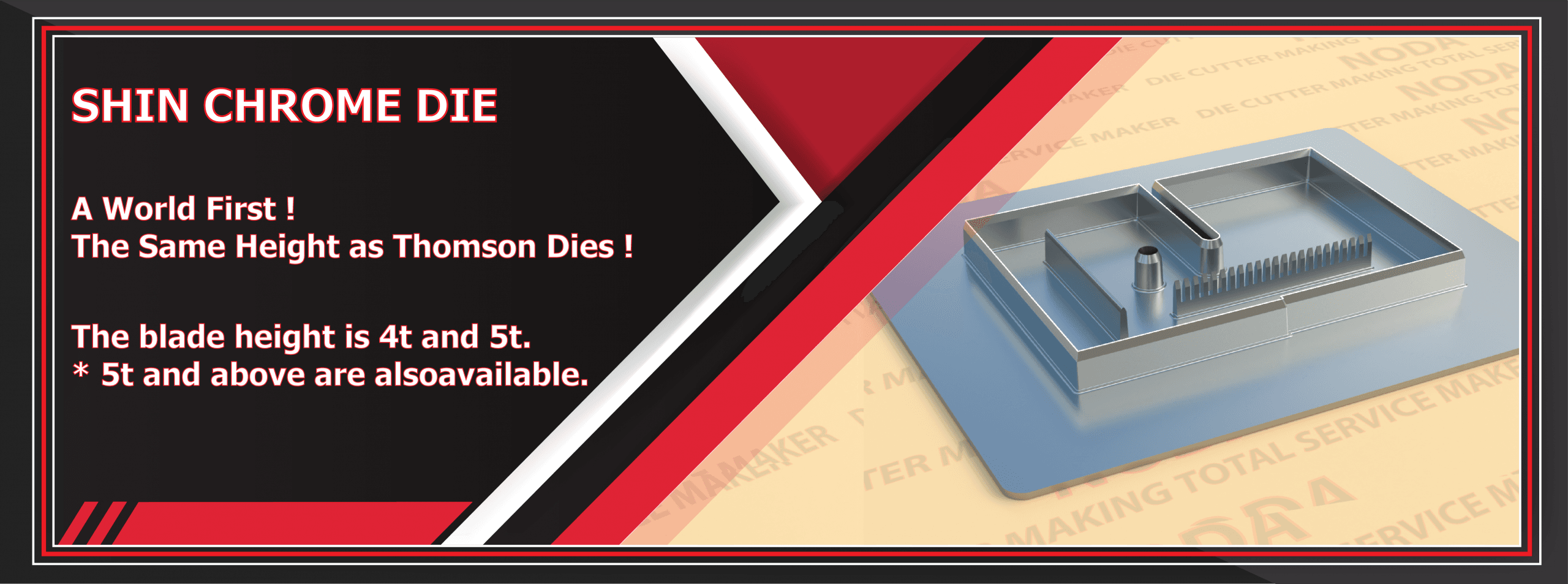

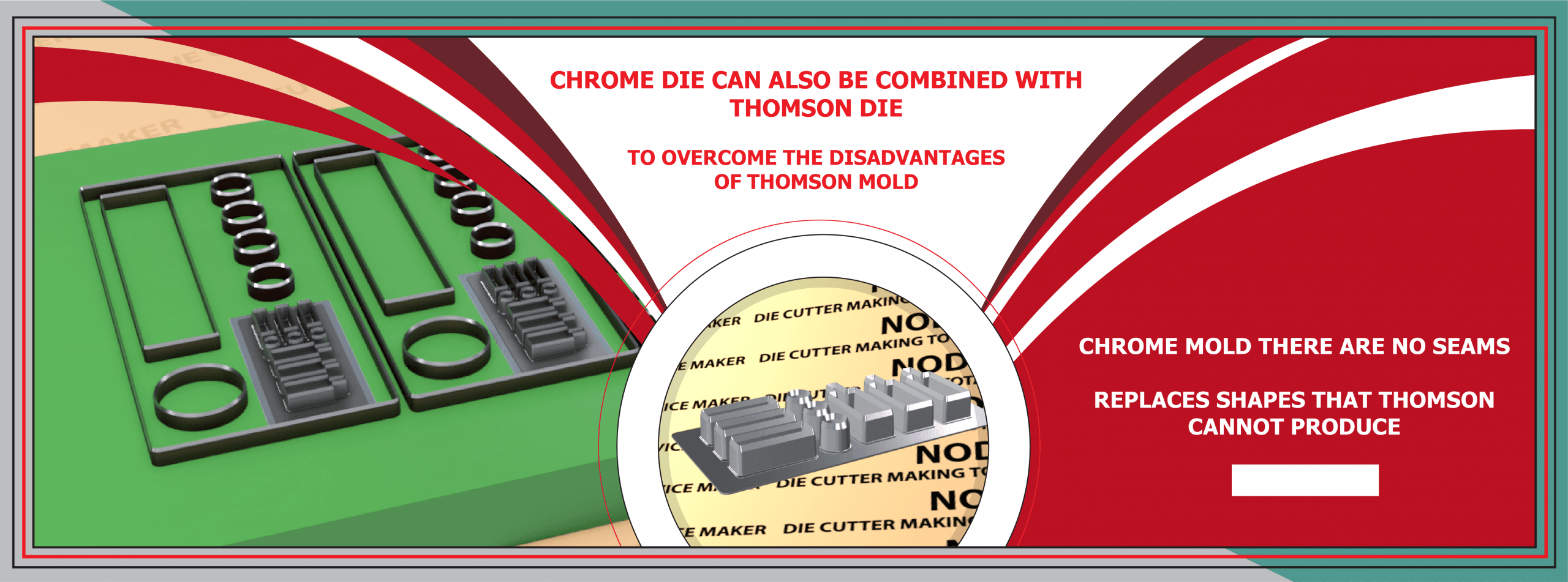

With Shin Chrome dies, we can produce any shape you need—customized precisely to your specifications. Designed for wastewater drainage applications, Shin Chrome dies save time and significantly enhance the durability of cutting blades.

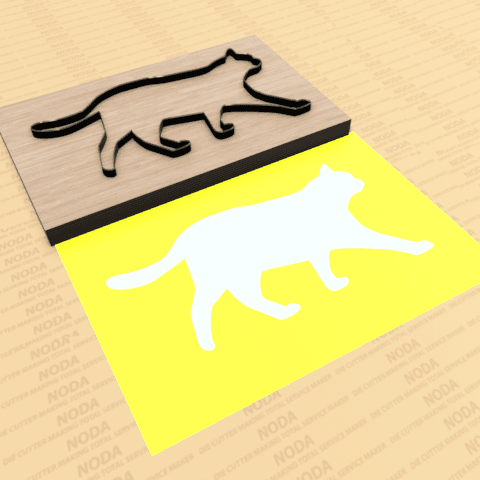

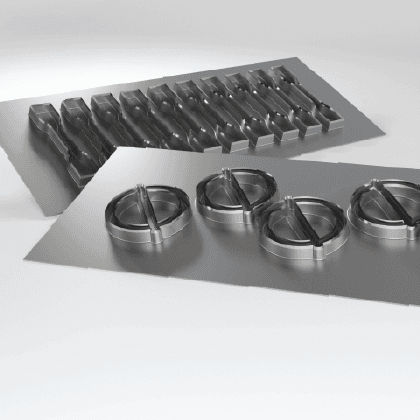

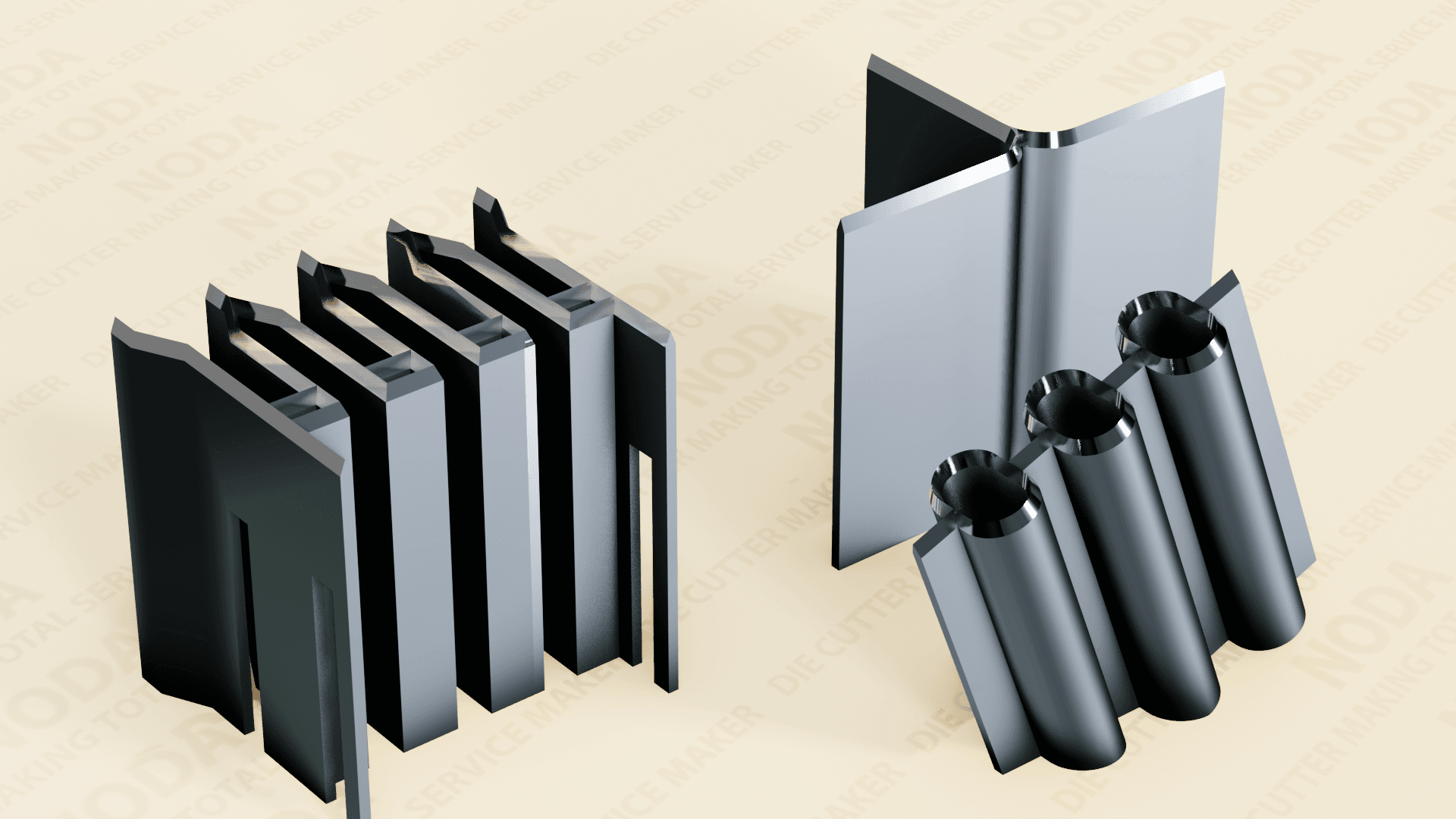

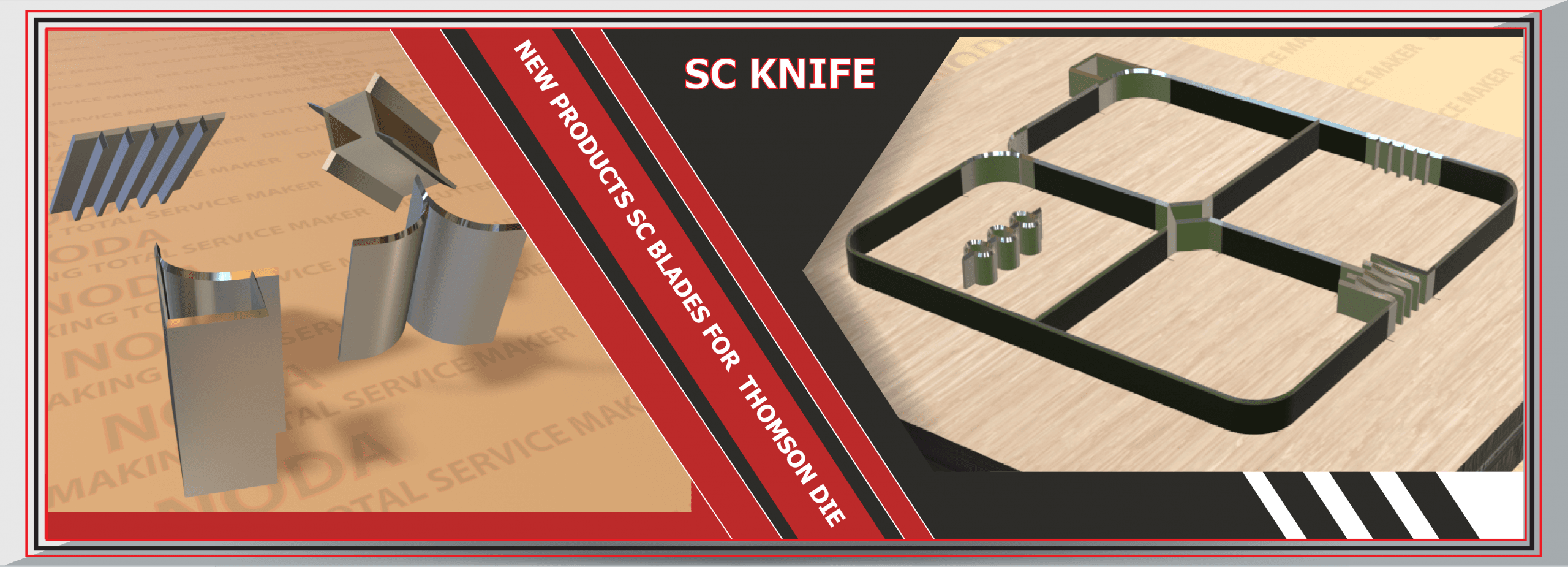

Introducing the SC Die Blade – NODA’s latest innovation in die cutting technology.

The SC Blade was developed to solve common issues found in traditional die blades, such as difficulty in cutting small shapes or areas where R and C corners are closely positioned—often leading to tearing or incomplete cuts during forming.

Crafted using high-precision CNC machining, the SC Blade has no welds or joints, resulting in superior strength, accuracy, and durability. It can be reused multiple times, significantly reducing production costs and improving overall cutting performance.

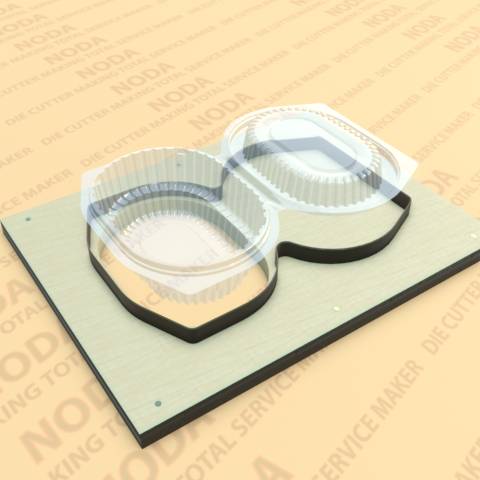

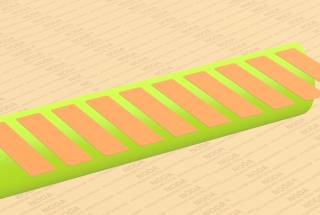

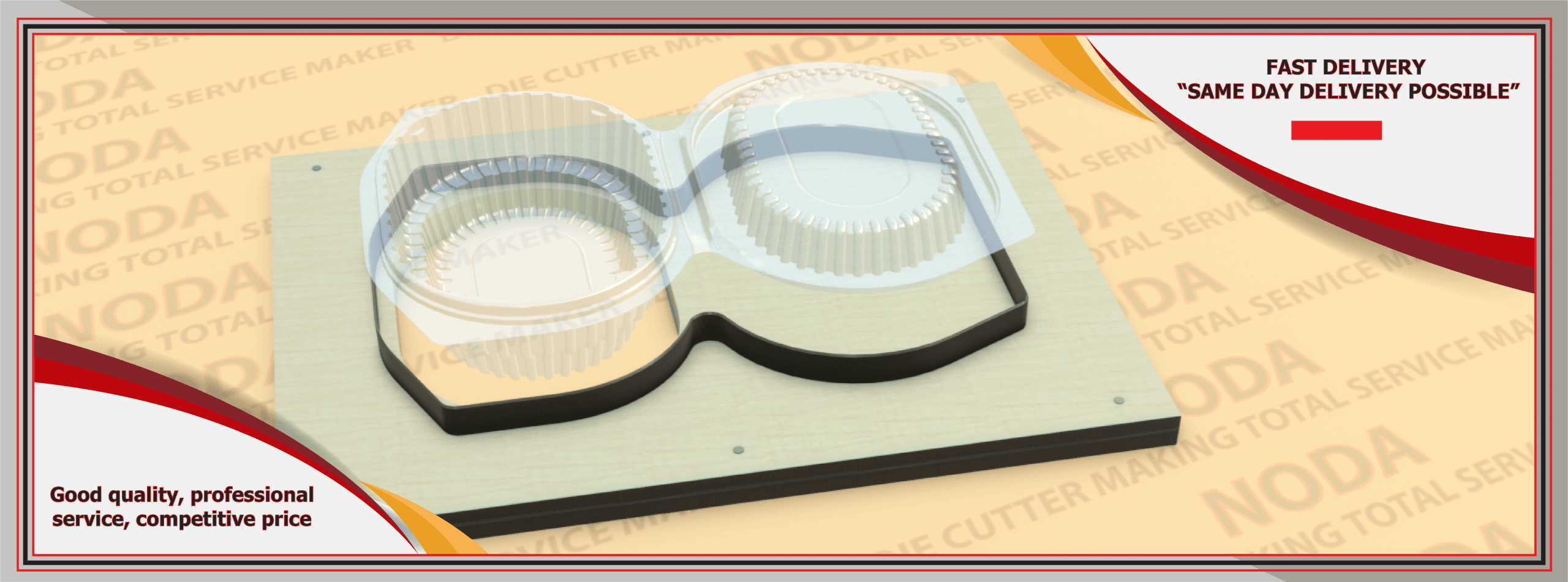

Understanding Half-Cut and Full-Cut in Label and Packaging Production

In the label and sticker manufacturing industry, half-cutting (ハーフカット or 半切り) refers to a die cutting technique where only the top layer (such as the sticker or label) is cut, while the backing paper (liner) remains intact. This allows for easy peeling and application, making it a preferred method for producing self-adhesive labels and stickers with precision.

In contrast, full-cutting (フルカット or 全抜き) means cutting through both the sticker and the backing paper completely. This method is typically used when separating individual pieces entirely is required.

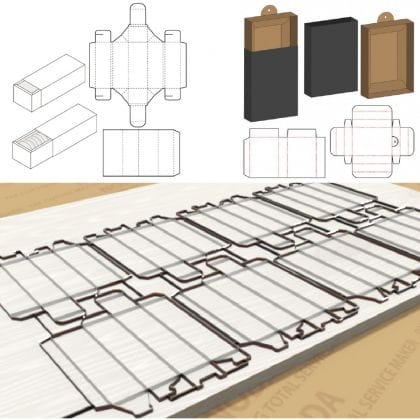

In the packaging industry, especially with paperboard thicker than 2mm, half-cutting is also used to partially cut or score the material. This technique allows for easier and cleaner folding, which is essential in producing high-quality packaging with structural integrity.

Half-cutting plays a critical role in enhancing product quality and production efficiency in the manufacturing of labels, stickers, and folding cartons. By enabling precision cutting, it supports better handling, cleaner edges, and a professional finish in the final product.